OUR TECHNOLOGY

DriJet

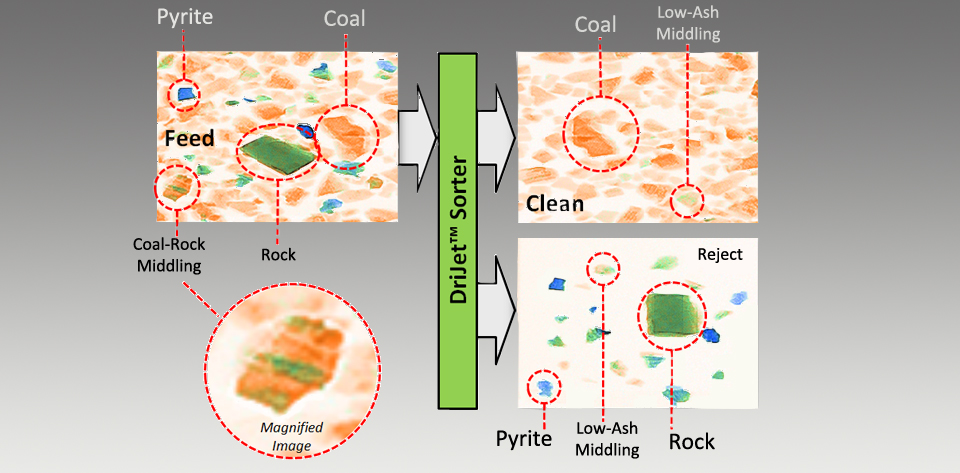

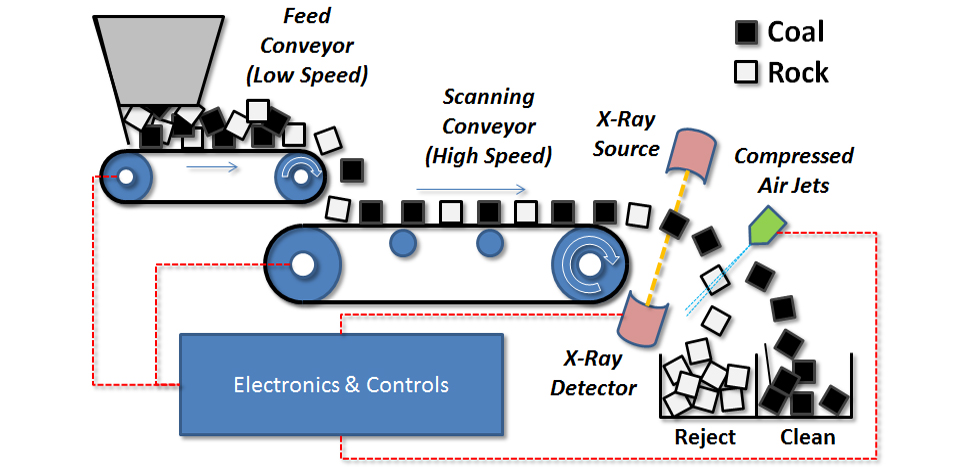

DriJet™ uses x-rays to measure the atomic weight of individual pieces of coal and rock, and precision air jets to separate the two fractions. It sorts not by specific gravity but by atomic weight.

DriJet efficiently removes ash and sulfur from coal for much less cost than other technologies.

The x-ray sensors sample individual pieces of rock and coal hundreds of times in just a few milliseconds. The jets use a small yet precise volume of air. For example an air table is a common specific gravity separation technology, and in comparison a DriJet uses 1/3 of 1% the amount of air.

A DriJet 100 can sort 20,000 pieces of coal and rock in one second with an error rate of less than 1%.

DriJet technology uses little power and has few moving parts. It uses no consumable chemicals or water at all. It has a small footprint. It can inexpensively remove ash and sulfur from coal right at the mine face.

DriJet saves money on trucking and on washing. The impact on mine economics can be enormous.